The printer.cfg File

I chose to generate my own initial configuration from previous knowledge while also referring to my other printers and Klipper’s configuration reference.

This document covers the step by step generation of my printer.cfg file.

![]() I found it easier to do some of the startup checks/tuning as the configuration was generated. For brevity of this document, I broke them out into a Startup Tuning sub document and linked out as needed.

I found it easier to do some of the startup checks/tuning as the configuration was generated. For brevity of this document, I broke them out into a Startup Tuning sub document and linked out as needed.

My configuration is broken down as follows:

printer.cfg

![]() Remember this is all specific to my particular machine. All pin definitions should be verified and changes made in accordance with the hardware in use.

Remember this is all specific to my particular machine. All pin definitions should be verified and changes made in accordance with the hardware in use.

A fresh Klipper & Mainsail installation should have generated a bare bones printer.cfg file.

[include mainsail.cfg]

[mcu]

serial: /dev/serial/by-id/<your-mcu-id>

[virtual_sdcard]

path: /home/E3NG/printer_data/gcodes

on_error_gcode: CANCEL_PRINT

[printer]

kinematics: none

max_velocity: 1000

max_accel: 1000

Make sure to keep the [include mainsail.cfg] and the information in the [printer] section. The entire [virtual_sdcard] section can be removed as it is duplicated in mainsail.cfg.

MCU Settings & Features

As the title suggests, this block holds the MCU definitions and enables Klipper features.

My primary mcu communicates via USB to CAN bridge and is defined with the following code. The canbus_uuid is unique per machine.

[mcu]

canbus_uuid: 027a94e7a31e

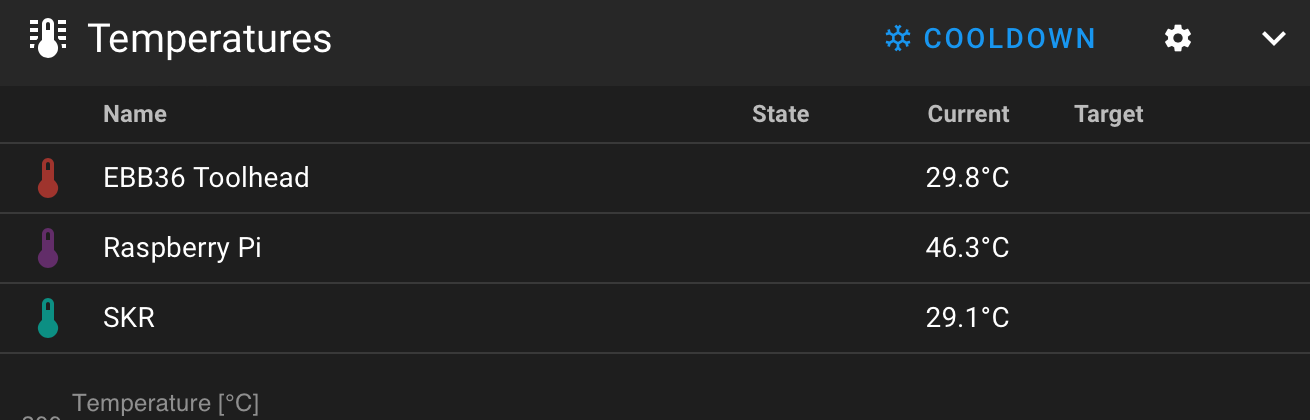

I also added a temperature reading to the frontend for this board by using the [temperature_sensor] option. Where “SKR” is my chosen name for the controller.

[temperature_sensor SKR]

sensor_type: temperature_mcu

min_temp: 0

max_temp: 100

The EBB36 CAN toolhead board was then added to the configuration.

[mcu EBB36_Toolhead]

canbus_uuid: cf152fa74cfc

Since this is an additional mcu, I gave it the name

EBB36_Toolhead. This will be referred to in later sections.

Once again, I added a temperature sensor to the fronted. This time I needed to define sensor_mcu to tell Klipper what MCU the sensor was located on.

[temperature_sensor EBB36_Toolhead]

sensor_type: temperature_mcu

sensor_mcu: EBB36_Toolhead

min_temp: 0

max_temp: 100

I perviously set up the Raspberry Pi host as an MCU, that needed to be defined as well along with a temperature sensor for it as the host. The host serial path should be the same regardless of machine or installation.

[mcu Raspberry_Pi]

serial: /tmp/klipper_host_mcu

[temperature_sensor Raspberry_Pi]

sensor_type: temperature_host

min_temp: 0

max_temp: 100

![]() The Pi has an integrated temperature sensor but not all host MCUs do.

The Pi has an integrated temperature sensor but not all host MCUs do.

Finally, I added the [exlcude_object] feature. This is also where I place any included config files.

[exclude_object]

[include mainsail.cfg]

A Save & Restart of the firmware should bring Mainsail back online with the above defined temperature sensors now visible on the frontend.

Motion

This section contains the printer kinematics, stepper motor configurations, and other motion related settings.

To start, the [printer] section needs to be updated. The Ender 3 NG uses corexy kinematics. The accelerations and velocities should also be set but can be tuned later. I started with the following settings:

[printer]

kinematics: corexy

max_velocity: 200

max_accel: 2000

max_z_velocity: 5

max_z_accel: 100

If a firmware restart is done at this point, an error regarding “step_pin” will appear. This is expected as we have yet to define any stepper motors. Therefore, I next defined the stepper motor configurations.

Stepper X/Y/Z

The stepper X/Y/Z settings can be pulled off of the generic BTT SKR Mini E3 v3 config with some minimal modifications. Remember, this board uses TMC2209 drivers, so both sections are needed for each motor.

The step, dir, enable, uart, and tx pins should all be the same. I added comments in the code below to denote what was changed from the generic config.

Stepper X (A Motor)

Additional configuration settings have been added for sensorless homing.

[stepper_x]

step_pin: PB13

dir_pin: !PB12

enable_pin: !PB14

microsteps: 32 #Increased from 16

rotation_distance: 40

endstop_pin: tmc2209_stepper_x: virtual_endstop #For sensorless homing. Also requires DIAG jumper. Hardware pin was ^PC0

position_endstop: 235 #Set to theoretical max and will be tuned.

position_min: 0 #Added for visibility and will be tuned.

position_max: 235 # Theoretical max. Will be tuned.

homing_speed: 25 #Decreased from 50.

homing_retract_dist: 0 #Disables second homing attempt. Must be disabled for sensorless homing.

[tmc2209 stepper_x]

uart_pin: PC11

tx_pin: PC10

uart_address: 0

interpolate: False #Disable interpolation

run_current: 0.7 # Default 0.580 | Calculated as 70% max_run_current where max_run_current=(rated_current * 0.707). For StepperOnline 17HS15-1504S-X1 motor ((1.50 * 0.707)*0.70=0.742).

stealthchop_threshold: 0 #Use spreadCycle. Default is 999999 for stealthChop

diag_pin: ^PC0 #Jumped endstop pin required for sensorless homing

driver_SGTHRS: 255 #Added at max sensitivity. Must be tuned for sensorless homing

Stepper Y (B Motor)

The stepper_y includes most of the same changes as stepper_x however I elected to use a physical endstop for this axis.

[stepper_y]

step_pin: PB10

dir_pin: !PB2

enable_pin: !PB11

microsteps: 32 #Increased from 16

rotation_distance: 40

endstop_pin: ^PC1

position_endstop: 235 #Set to theoretical max and will be tuned.

position_min: 0 #Added for visibility and will be tuned.

position_max: 235

homing_speed: 25 #Decreased from 50.

[tmc2209 stepper_y]

uart_pin: PC11

tx_pin: PC10

uart_address: 2

interpolate: False #Disable interpolation

run_current: 0.7 # Default 0.580 | Calculated as 70% max_run_current where max_run_current=(rated_current * 0.707). For StepperOnline 17HS15-1504S-X1 motor ((1.50 * 0.707)*0.70=0.742).

stealthchop_threshold: 0 #Use spreadCycle. Default is 999999 for stealthChop

Stepper Z

The Z axis does not and should not use sensorless homing. My build currently uses a CR Touch and as such this section is immediately followed up by a [bltouch] configuration. The base config is outlined below with changes in the comments.

[stepper_z]

step_pin: PB0

dir_pin: PC5

enable_pin: !PB1

microsteps: 16

rotation_distance: 8

gear_ratio: 42:20 #Add the 42 tooth printed pulley to 20T motor pulley ratio

endstop_pin: probe: z_virtual_endstop # For CR/BL Touch. Hardware endstop pin was ^PC2

#position_endstop: 0.0 Remove this since a probe is used

position_max: 245 #Set to theoretical max and will be tuned.

position_min: 0 #Added for visibility and will be tuned.

[tmc2209 stepper_z]

uart_pin: PC11

tx_pin: PC10

uart_address: 1

run_current: 0.7 # Default 0.580 | Calculated as 70% max_run_current where max_run_current=(rated_current * 0.707). For StepperOnline 17HS15-1504S-X1 motor ((1.50 * 0.707)*0.70=0.742).

stealthchop_threshold: 0 #Use spreadCycle. Default is 999999 for stealthChop

If the firmware is saved and restarted now an error regarding probe should appear. Again, this is an expected error as the probe still needs to be configured.

Probe

I’ve included the probe or [bltouch] configuration next. It is required in the case a probe is being used as the Z endstop.

![]() Verify the probe and board pins. My installation has the CR Touch connected to the endstop connector on the EBB36 and NOT the standard probe pins.

Verify the probe and board pins. My installation has the CR Touch connected to the endstop connector on the EBB36 and NOT the standard probe pins.

[bltouch]

sensor_pin: ^EBB36_Toolhead: PB7

control_pin: EBB36_Toolhead: PB6

y_offset: -18 #Measured per printer/mount. `x_offset` can also be specified.

z_offset: 0 # Required initially but will be tuned.

Addtional features of the probe are discussed [here].

At this point, all of the motion components have been defined. A Save & Restart should bring Klipper back online with no errors and some motion control available on the front end.

I suggest completing some basic motion checks and tuning before continuing to build the configuration.

Extruder

This section defines the extruder motor, heater, and limits. Recall, my build uses an EBB36 toolhead board so all of the pin definitions are in relation to that. Additionally, some configurations were modified for use with the Stealthbuner. Things like PID control and rotation distance will need to be tuned on a per machine basis. Also, rather than specify pressure advance, I use slicer macros to push the value on a per filament basis.

[extruder]

step_pin: EBB36_Toolhead: PD0

dir_pin: EBB36_Toolhead: PD1

enable_pin: !EBB36_Toolhead: PD2

rotation_distance: 22.23 #Default value. Will be tuned.

gear_ratio: 50:10 #Stealthburner/CW2 ratio

microsteps: 32

nozzle_diameter: 0.4

filament_diameter: 1.750

heater_pin: EBB36_Toolhead: PB13

sensor_type: Generic 3950

sensor_pin: EBB36_Toolhead: PA3

control: pid # Generic PID settings. Will be tuned.

pid_Kp: 21.527

pid_Ki: 1.063

pid_Kd: 108.982

min_temp: 0

max_temp: 285

max_extrude_only_distance: 101

[tmc2209 extruder]

uart_pin: EBB36_Toolhead: PA15

interpolate: False

run_current: 0.6

sense_resistor: 0.110

stealthchop_threshold: 0 #Set to 0 for spreadcycle, avoid using stealthchop on extruder

If everything is correctly defined, the extruder temperature should now be visible on the Mainsail frontend.

![]() Make sure the extruder temperature is holding steady and not heating. If it is heating, then shut down the printer and start troubleshooting the wiring and/or config definitions.

Make sure the extruder temperature is holding steady and not heating. If it is heating, then shut down the printer and start troubleshooting the wiring and/or config definitions.

Other error messages are usually fairly detailed and can assist if issues arise.

I’ve also included the configuration for the toolhead fans in this section. It made sense to me as they are needed for proper extruder operation.

[fan]

pin: EBB36_Toolhead: PA1

[heater_fan hotend_fan]

pin: EBB36_Toolhead: PA0

heater: extruder

heater_temp: 50.0

Once the fans are defined they should also appear on Mainsail.

I recommended verifying the extruder functions at this stage.

Bed Heater

Similar to the extruder section the heated bed needs to be defined.

[heater_bed]

heater_pin: PC9

sensor_type: ATC Semitec 104GT-2

sensor_pin: PC4

min_temp: 0

max_temp: 130

control: pid # Generic PID settings. Will be tuned.

pid_Kp: 21.527

pid_Ki: 1.063

pid_Kd: 108.982

Once again, heater bed should now be visible on the front end with a steady temperature.

The basic printer.cfg has been built. Before starting to print, some minimal checks and startup tuning is required if it has not already been done.